|

I have two kilns in my studio, they both have a digital controller which enables me to create bespoke programs with several segments to suit whatever ware I am firing. The problem with firing ceramics is that there are so many variables it can make your head spin! I have had my fair share of problems with firing work, trying to navigate your way around ceramic forums, specialist websites like Digital Fire to get the optimal firing for your work is a minefield. Every kiln is different, the age of the elements, density of the kiln bricks, size of kiln, how it’s loaded and how well its calibrated all have an effect on the overall firing results, and this is just oxidation firings, so most of the firing schedules I do are mainly through trial and error. I have never fired anything in gas reduction, or a wood fired kiln and have had one very limited experience of Raku firing.

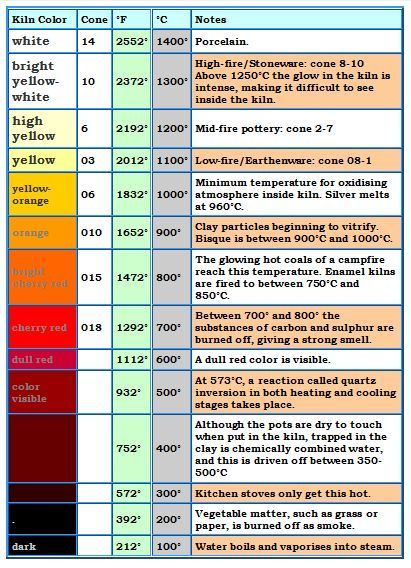

It can be hard to know how to problem solve when things go wrong, and I found the session on glazing and firing really helpful in helping me to understand why some of the issues I have been experiencing may have occurred. I was really confused about quartz inversion and when ware can be at risk of cracking in a kiln, I thought a firing schedule had to go slowly both up and down through quartz inversion, as it turns out it.s more important that this happens during cooling rather than heating, especially for wide and flat pieces of ware so I have made changes as a consequence of this. Also I thought I was firing work slowly and when I looked at the schedules used at Uni I was no where near! So again I have altered my own firings, especially for thicker, larger pieces. I also found the colour guide useful in helping me to gauge what the temperature inside the kiln is by the colour of the heat glow. I guess that it’s easy to become reliant on digital controllers and electric thermocouples, but understanding what’s going on by observation will be really helpful as I plan to do some alternative firing at home, and gauging the temperature is often done through the colour of the heat work in the kiln. Comments are closed.

|

AuthorStella Boothman Archives

February 2024

Categories |

RSS Feed

RSS Feed